- Produktspezifikationen

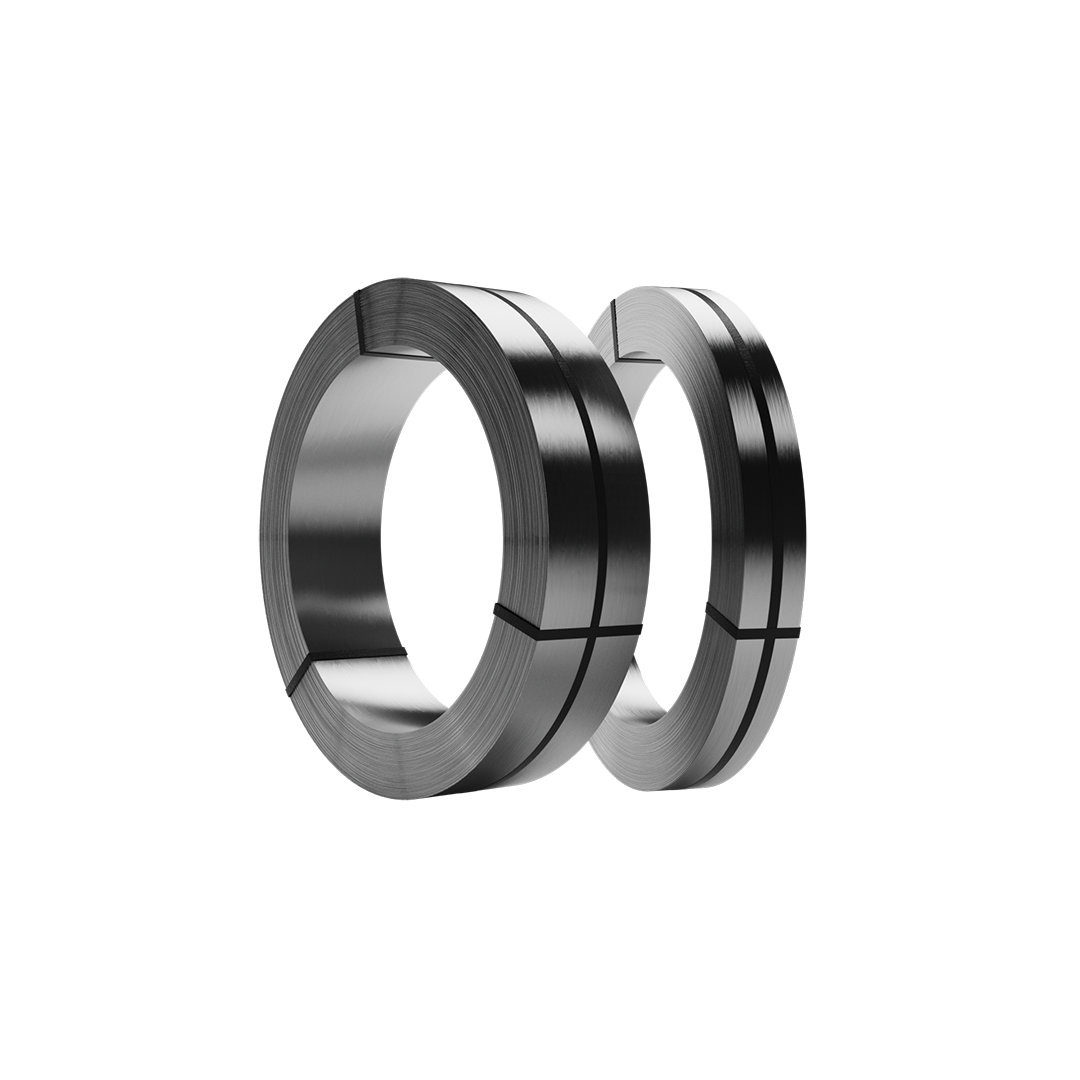

- Verpackung

- Bitte um Angebot

CEWELD® SA Nicro 690 strip is resistant to a wide range of corrosive media and atmospheres. The high chromium content makes the deposit particularly suitable for strongly oxidising conditions. The high chromium content also confers resistance to high-temperature corrosion in gases having an oxidising and sulphidising effect. Due to its high nickel content, CEWELD® SA Nicro 690 Strip is exceptionally resistant to stress corrosion cracking which can occur in the primary water loops of nuclear power stations. The material also shows good resistance in mixtures of nitric and hydrofluoric acid. It demonstrates remarkable behaviour in concentrated (98.5 %) sulphuric acid at temperatures of up to 150 °C (300 °F).

CEWELD® SA Nicro 690 Strip is mainly used for ESW and SAW cladding on steels to obtain corrosion and heat resistant layers. Go to CEWELD® FL 860 ESHC suifable flux.