- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

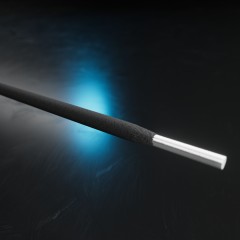

CEWELD® E DUR 68 T is used where high where high abrasive wear occurs, as it offers extremely high resistance to abrasion.

Armor plating of parts that are exposed to high abrasion with low impact stress, e.g.: Sand pump housings, Paddle wheels, scrapers, Press and Screw conveyors, etc.

CEWELD® E DUR 68 T is used where high where high abrasive wear occurs, as it offers extremely high resistance to abrasion.

Armor plating of parts that are exposed to high abrasion with low impact stress, e.g.: Sand pump housings, Paddle wheels, scrapers, Press and Screw conveyors, etc.

CEWELD® E DUR 68 T is a thick coated electrode with high recovery 200%. Ledeburitic weld metal structure. Application is for parts that are exposed to strong abrasive wear. Operating temperature is from RT to 300 °C. CEWELD® E DUR 68 T deposits a virtually slag-free weld metal with uniform welding behavior.

Sugar mill knives and Hammers, Clinker crushers, Sintering lines, Fire gratings, Mixer blades, Gravel washing equipment, Ceramic mixer blades, Extruders etc….

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 68 HRc |